Designed for medium-pressure industrial applications, POOCCA V Series pumps are known for their low noise, durability and efficiency.

Single vane pump series are: V10, V20, 20V, 25V, 35V, 45V, 50V

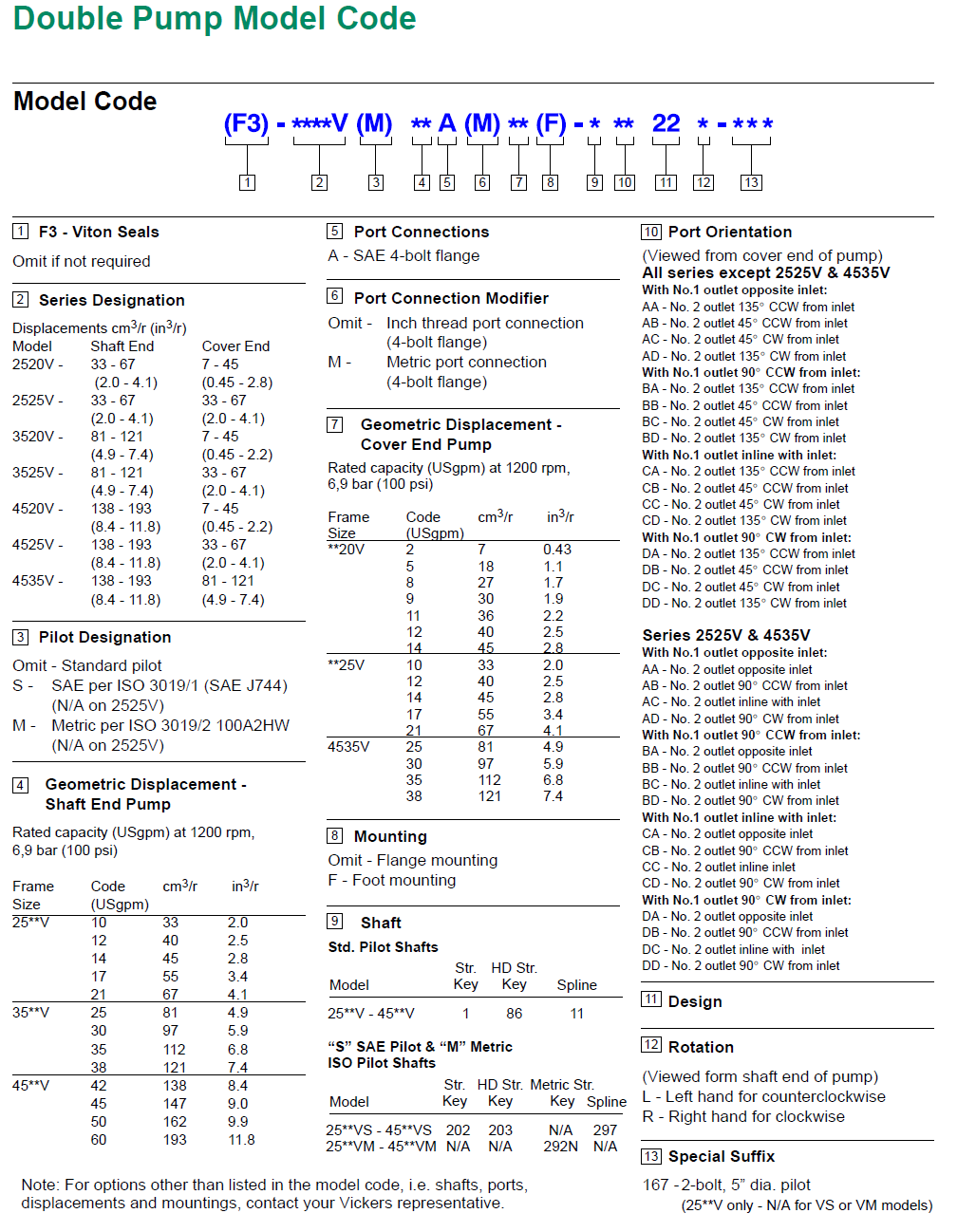

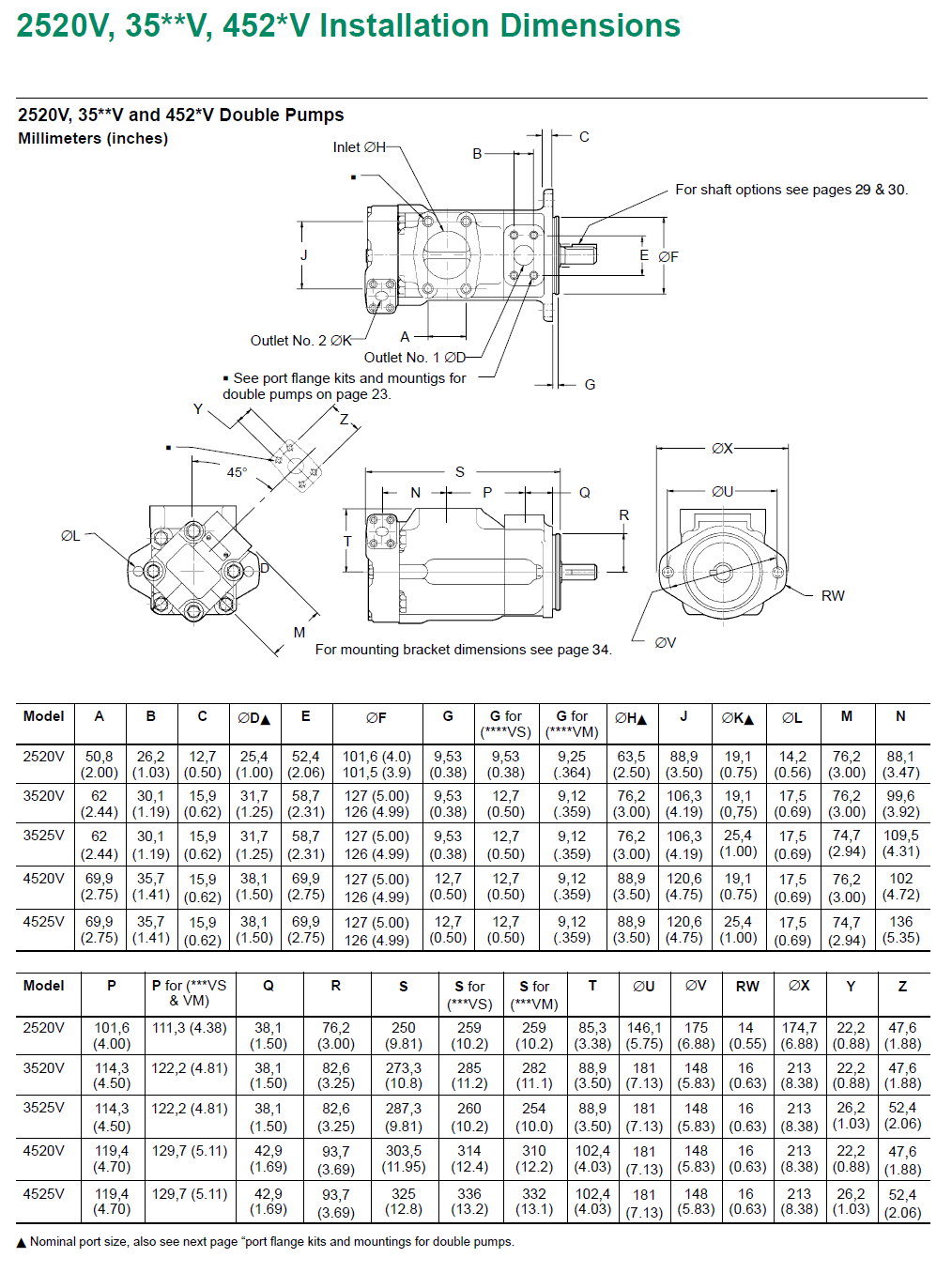

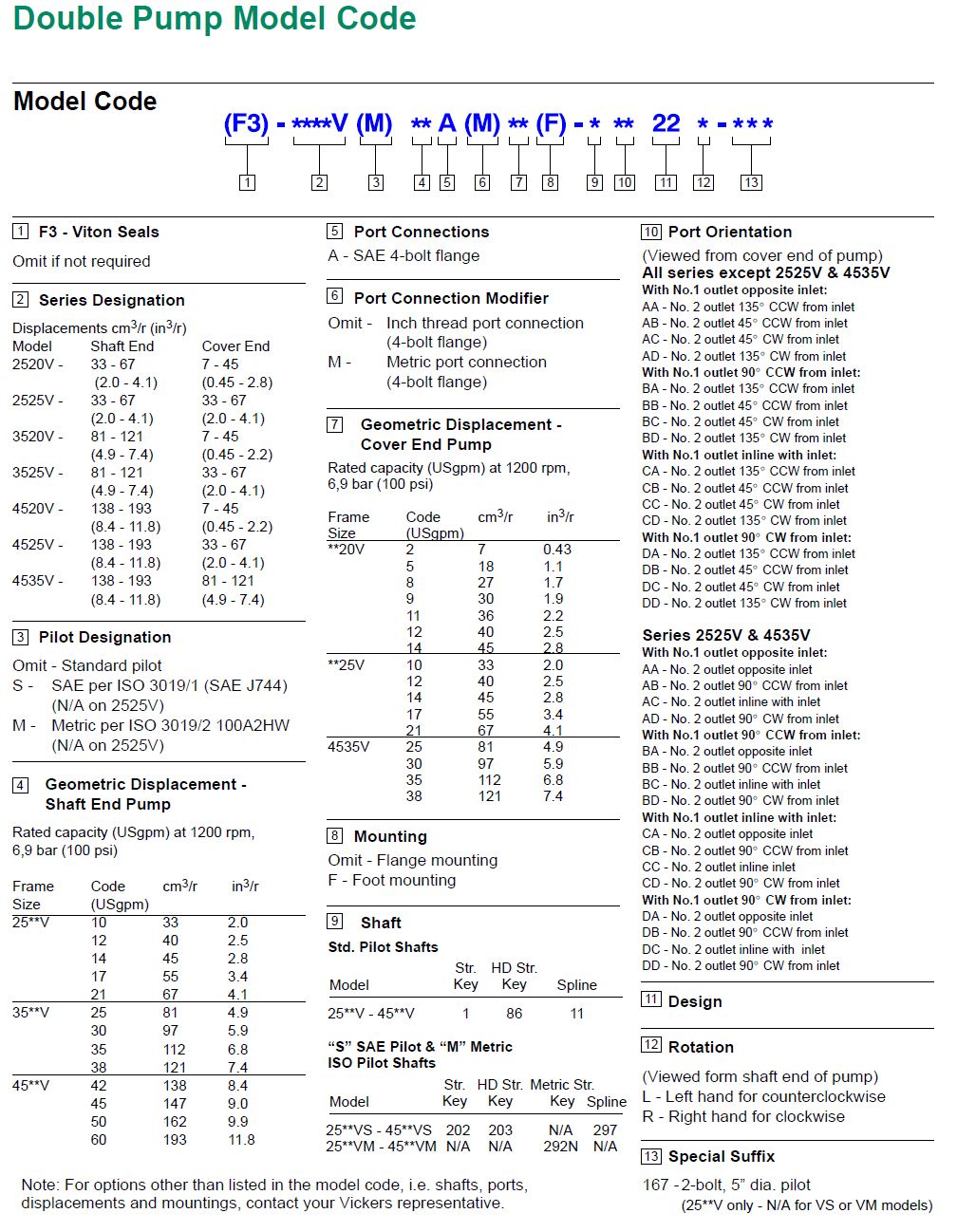

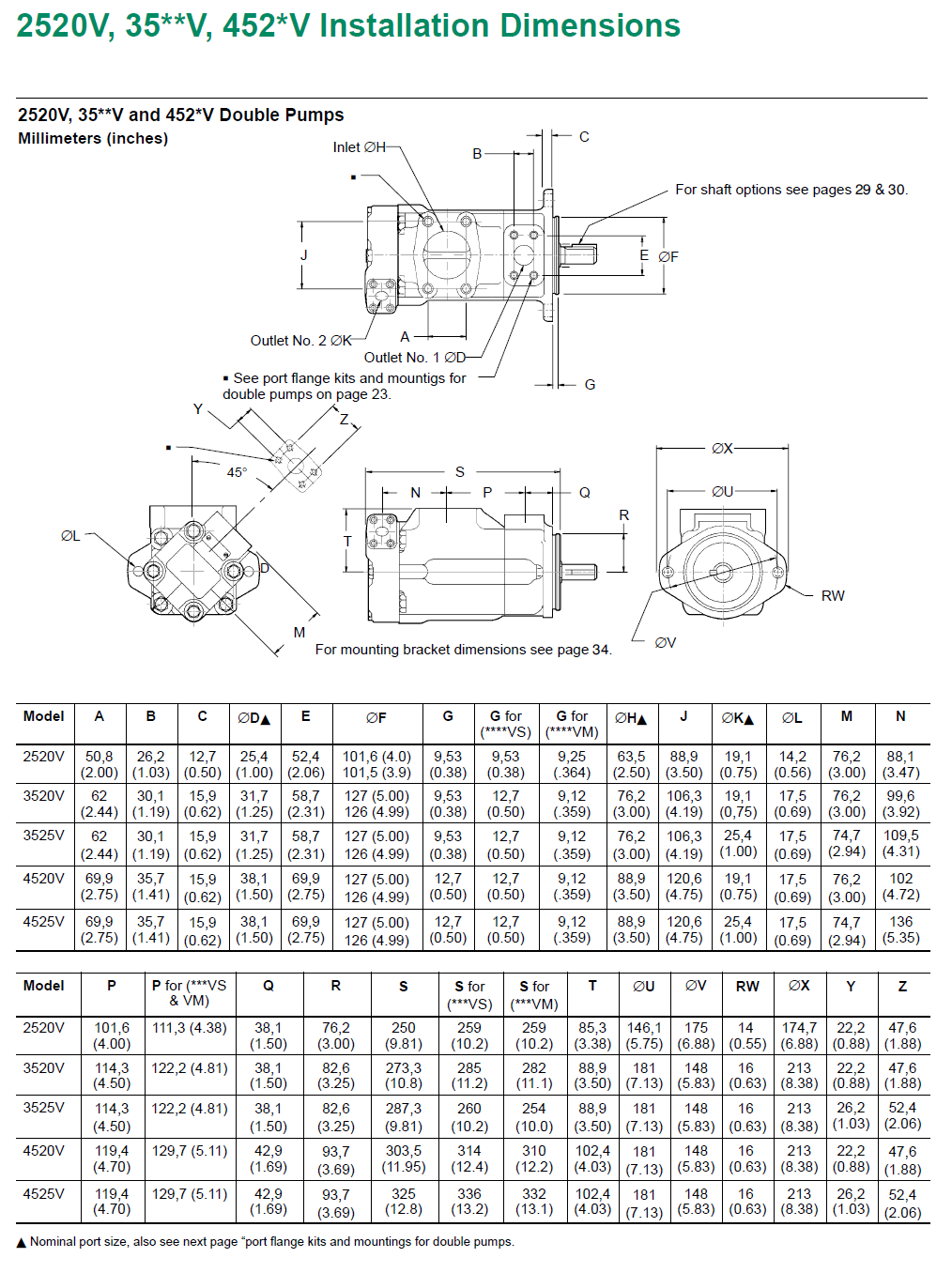

The series of double vane pumps are: V2010, V2020, 2520V, 3520V, 3525V, 4520V, 4525V, 4535V.

POOCCA offers the most complete line of hydraulic intra vane pumps for industrial applications. A wide variety of single and multiple configurations enables you to select the precise pump or combination best suited for your application.

Performance

These cost–effective pumps provide volumetric efficiencies of more than 90% and sound levels as low as 62 dB(A) with operating pressures to 207 bar (3000 psi).

General Description

Intra vane pumps provide longer life,increased productivity and application versatility. Extremely low sound levels are compatible with the most demanding industrial applications. Compact size and ease of service allow maximum equipment design flexibility.Pumps are available in single, double and thru-drive configurations.

Features and Benefits

High operating pressure capabilities in compact packages provide high power to weight ratios and lower installed costs.

Low noise characteristics inherent in intravane design enhance operator comfort.

Twelve vane system provides low amplitude flow pulsations resulting in low system noise characteristics.

Hydraulic balancing, designed to prevent internally-induced radial shaft and bearing loads, provides long life.

Double pumps and thru-drive arrangements save installation space and cost by eliminating double shaft extension electric motors or by reducing the number of motors and drive couplings.

Thru-drive models provide valuable circuit design flexibility, such as having fixed and variable displacement models on a single input drive.

Sixteen flow displacements and high operating pressure capabilities provide optimum selection and single-source capability for your complete range of flow and pressure requirements.

Factory tested cartridge kits provide new pump performance upon installation.

ThFactory tested cartridge kits provide new pump performance upon installation.e cartridge kit design offers fast and efficient field serviceability. The cartridge is independent of the drive shaft, allowing for easy change of flow capacity and servicing without removing the pump from its mounting.

Inlet and outlet ports can be oriented in four different positions relative to each other, providing greater installation flexibility and ease of machine design.

| Model | Code | Using anti-wear oil or phosphate ester fluid * | Using water-in-oil emulsions | Using water glycol fluid |

| 20V | 2 | 138 (2000) | 69 (1000) | 138 (2000) |

| 20V | 5, 8, 11 | 207 (3000) | 69 (1000) | 159 (2300) |

| **20V | 12 | 159 (2300) | 69 (1000) | 159 (2300) |

| **20V | 14 | 138 (2000) | 69 (1000) | 138 (2000) |

| 25V | 10, 12, 14, 17, 21 | 172 (2500) | 69 (1000) | 159 (2300) |

| 25VT | 12, 14, 17, 21 | 172 (2500) | 69 (1000) | 159 (2300) |

| 25**V | 12, 14, 17, 21 | 172 (2500) | 69 (1000) | 159 (2300) |

| **25V | 12, 14, 17, 21 | 172 (2500) | 69 (1000) | 159 (2300) |

| 35V | 25, 30, 35, 38 | 172 (2500) | 69 (1000) | 159 (2300) |

| 35VT | 25, 30, 35, 38 | 172 (2500) | 69 (1000) | 159 (2300) |

| 35**V | 25, 30, 35, 38 | 172 (2500) | 69 (1000) | 159 (2300) |

| **35V | 25, 30, 35, 38 | 172 (2500) | 69 (1000) | 159 (2300) |

| 45V | 42, 45, 50, 60 | 172 (2500) | 69 (1000) | 159 (2300) |

| 45VT | 42, 50, 60 | 172 (2500) | 69 (1000) | 159 (2300) |

| 45**V | 42, 50, 60 | 172 (2500) | 69 (1000) | 159 (2300) |